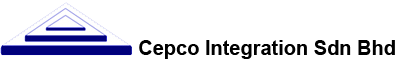

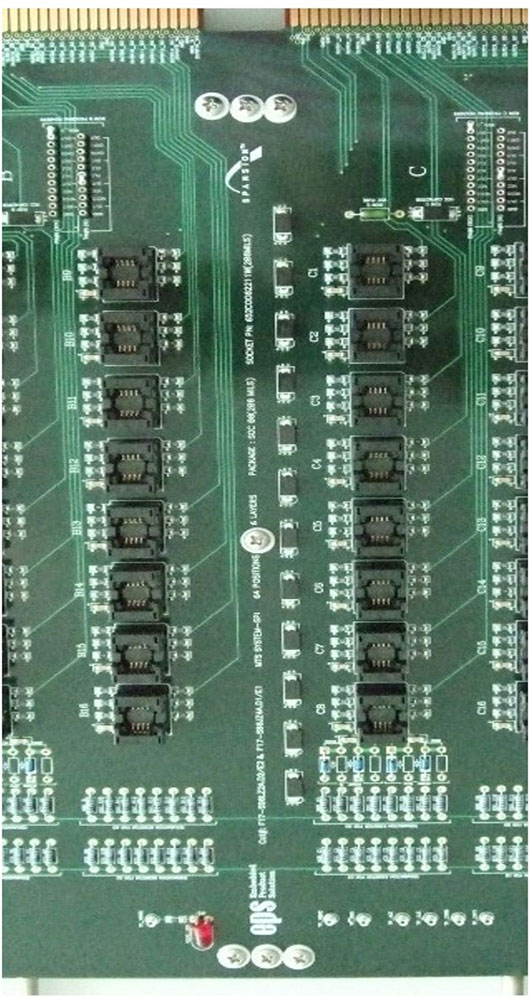

- Suitable to be used in hast environment

- Leakage or shorting in hast environment is prevented by a layer of conformal coating

- High temperature board materials are used to prolong the life span of the board

- 4 – 8 layers design

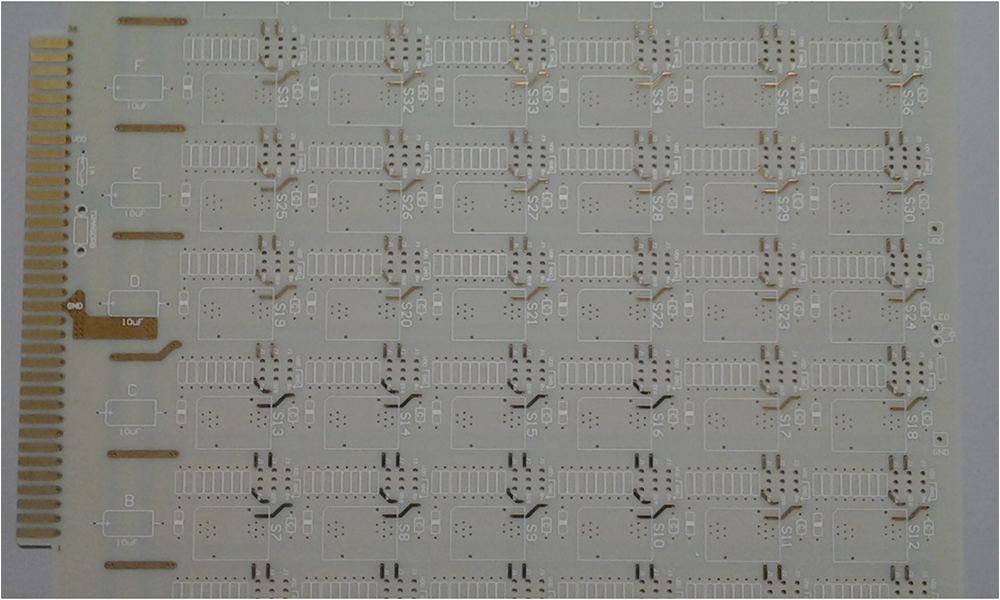

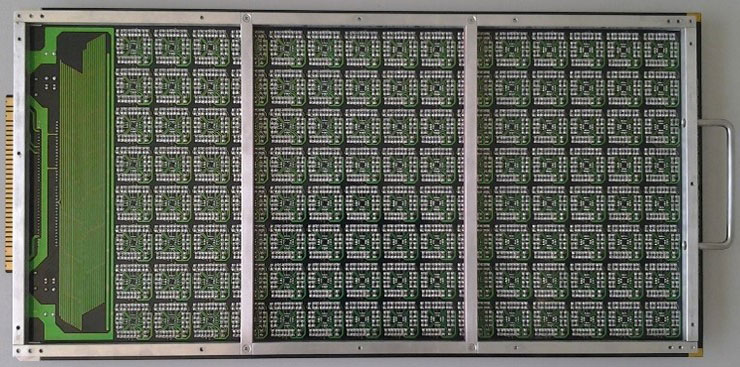

- Suitable to be used in high or ambient temperature environment

- Real time monitoring burn-in

- Signal trace impedance is controlled typically at 75Ω

- 6 – 12 layers design

- Signal termination and daisy chain routing are designed to maintain signal integrity

- Board materials are used to prolong the life span of the board

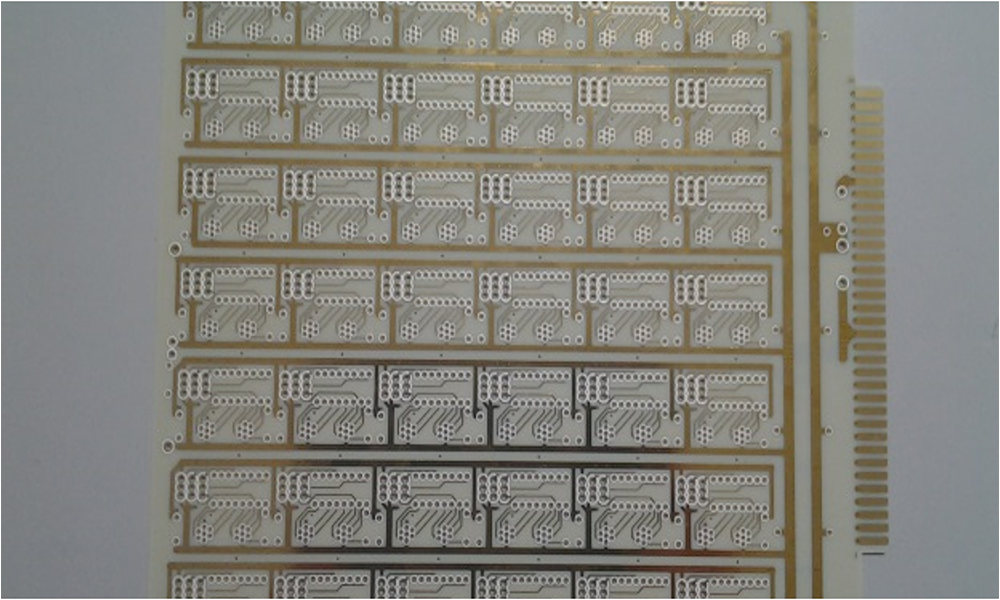

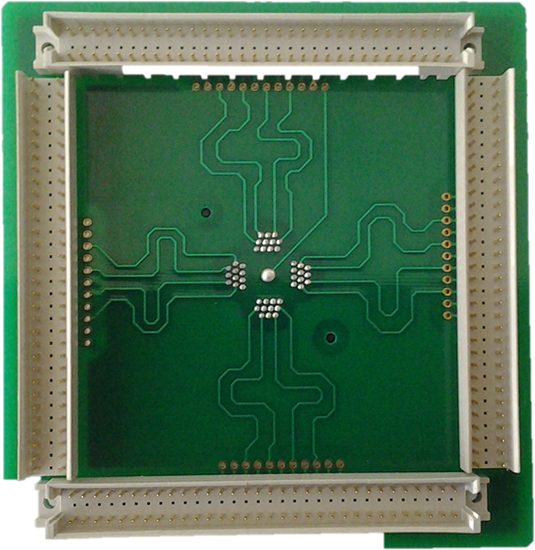

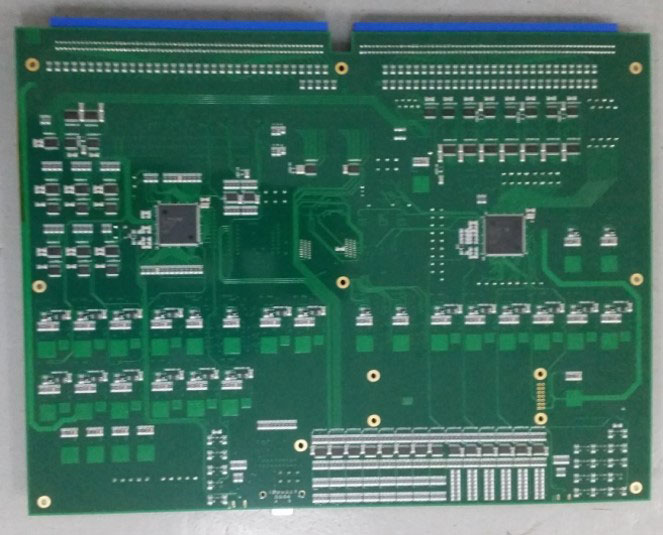

- Suitable to be used in high temperature environment

- Dynamic burn-in where signals are pumped in to stress the DUT

- 6 – 10 layers design

- Signal trace impedance is controlled typically at 50Ω

- High temperature board materials are used to prolong the life span of the board

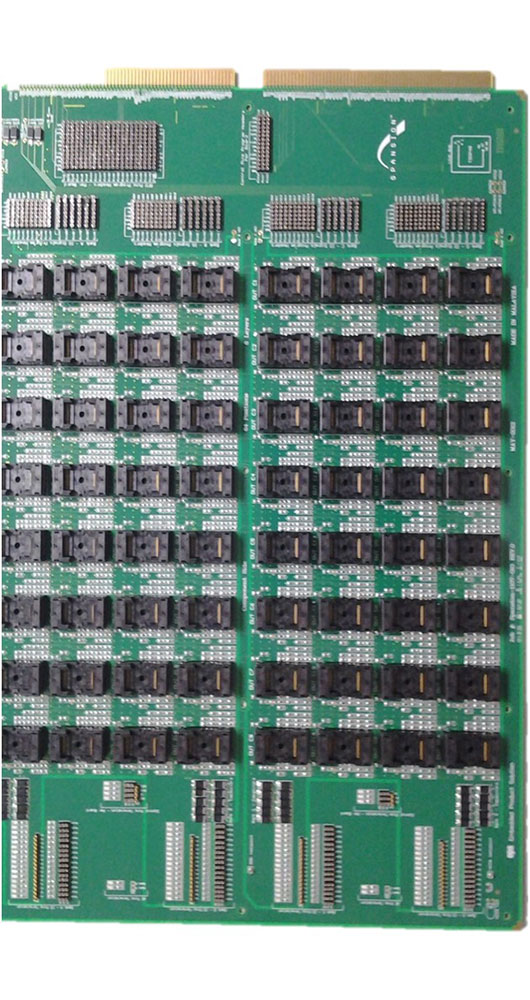

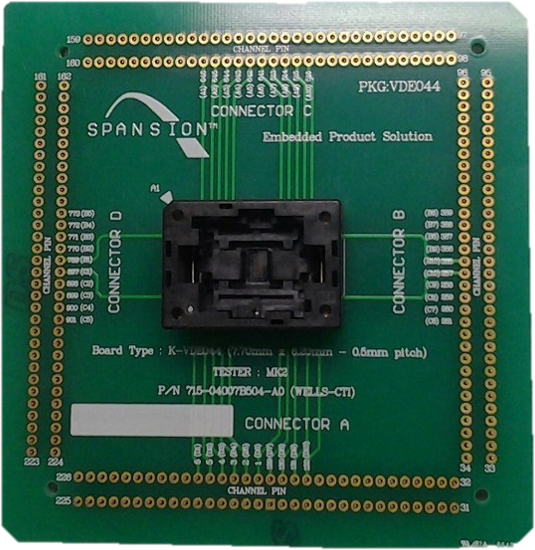

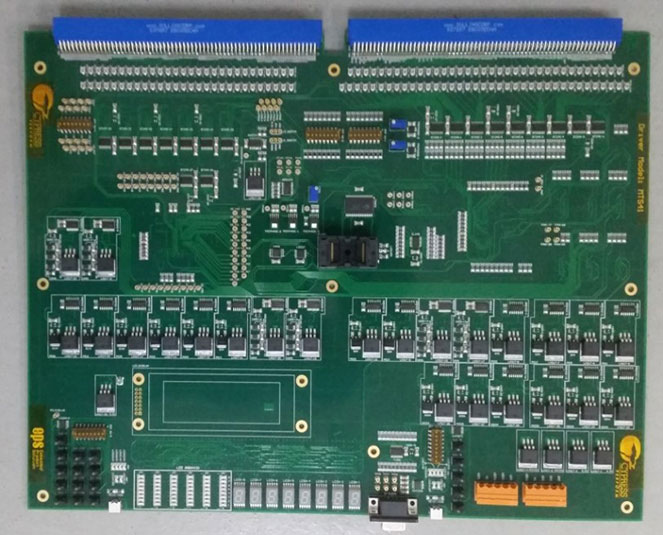

- ESD or latch up board

- All the signals trace are having the same propagation delays

- Logic Sequencer address generator

- Customize pattern address generator

- Able to support address from A0 to A38

- 0.5A Output pulse current per channel

- Suitable to be used as memory device burn in driver board